Pigment dispersions in powder form suitable for colouring:

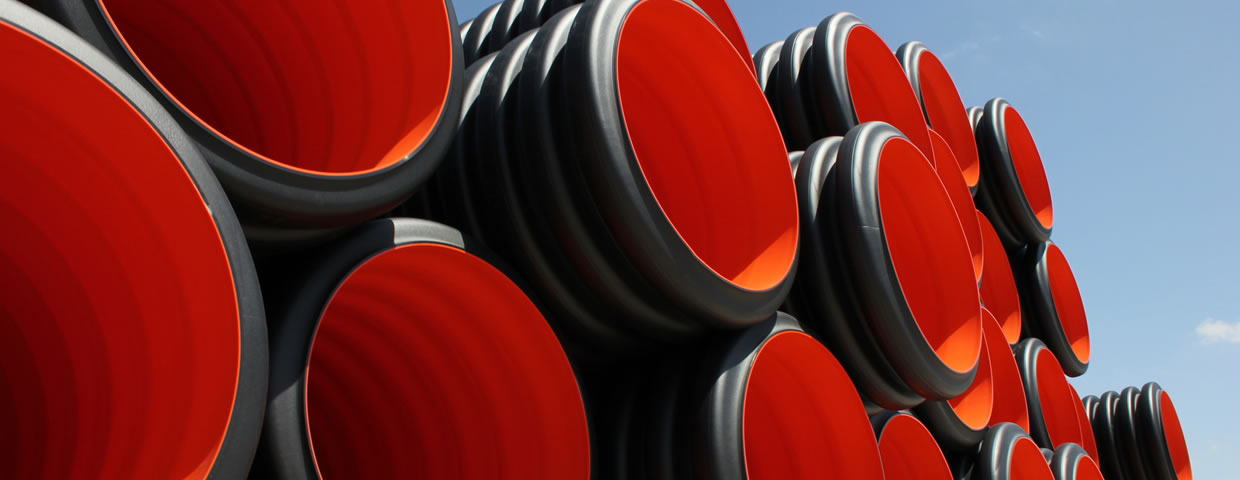

• VINYL RESINS: calendered rigid and semi-rigid PVC, extruded rigid PVC and injection moulded PVC

• POLYOLEPHINIC RESINS: PE and PP in powder form for injection and rotational moulding

• COMPOSITE AND ENGINEERED STONE

Concentrates of dispersed pigments suitable for colouring:

• POLYESTHER RESINS in pultrusion and centrifugation processes and SMC/BMC production

• VINYL RESINS: Plastisol for spreading and moulding, PVC compounds for rigid/semi-rigid and flexible calendered, PVC compounds for blowing and injection moulding

• POLYURETHANIC RESINS in spreading and injection moulding processes for flexible, rigid and integral expanded foams

• THERMOPLASTIC RESINS: Polyolephinic (PE-HD/LD and PP), Styrene (PS, SB, ABS, SAN), Polyacrilic, Polyamide, Acetal, etc. for extrusion, injection moulding, blowing, etc.

Concentrates of dispersed pigments in granule form that are suitable for colouring most thermoplastic materials in several production processes.

Dispersed pigments are also available in micro-granules form uniting the advantages of powder dry blends and common masterbatches.

For colouring:

Thermoplastic materials

Composite materials

Dispersion of pigments

Dispersion is an essential process in order to maximize the yield of a pigment and to achieve the best balance between a stronger colouring and the percentage of pigment to obtain optimal results.

Because pigments are not primary particles, they are agglomerates. Through dispersion it is possible to de-agglomerate pigments ensuring to reach the best yield using the fewer possible amount of pigment.

Dispersion of pigments is fundamental for every commercial application that aim to perfect aesthetic results.

Advantages

Dispersion allows to express to the maximum terms the yield of a pigment, breaking up the agglomerated particles and distributing them uniformly in a vehicle. The result is an excellent coloring performance, due to the superior yield of the dispersed pigment.

Pigments are carefully milled and uniformly dispersed in the vehicle, allowing to obtain regular and homogeneous productions. The study and analysis of pigments also allows us to support customers in order to obtain stable and repeatable results.

Through dispersion we ensure the achievement of the best yield using the least amount of pigment possible. This implies a reduction in costs with consequent economic savings.

Thanks to dispersion, pigment agglomerates are broken down until reaching high refining stages. Pigment particles are evenly distributed in the vehicle avoiding production defects and consequently reducing scraps.